Table of Contents

FAQ

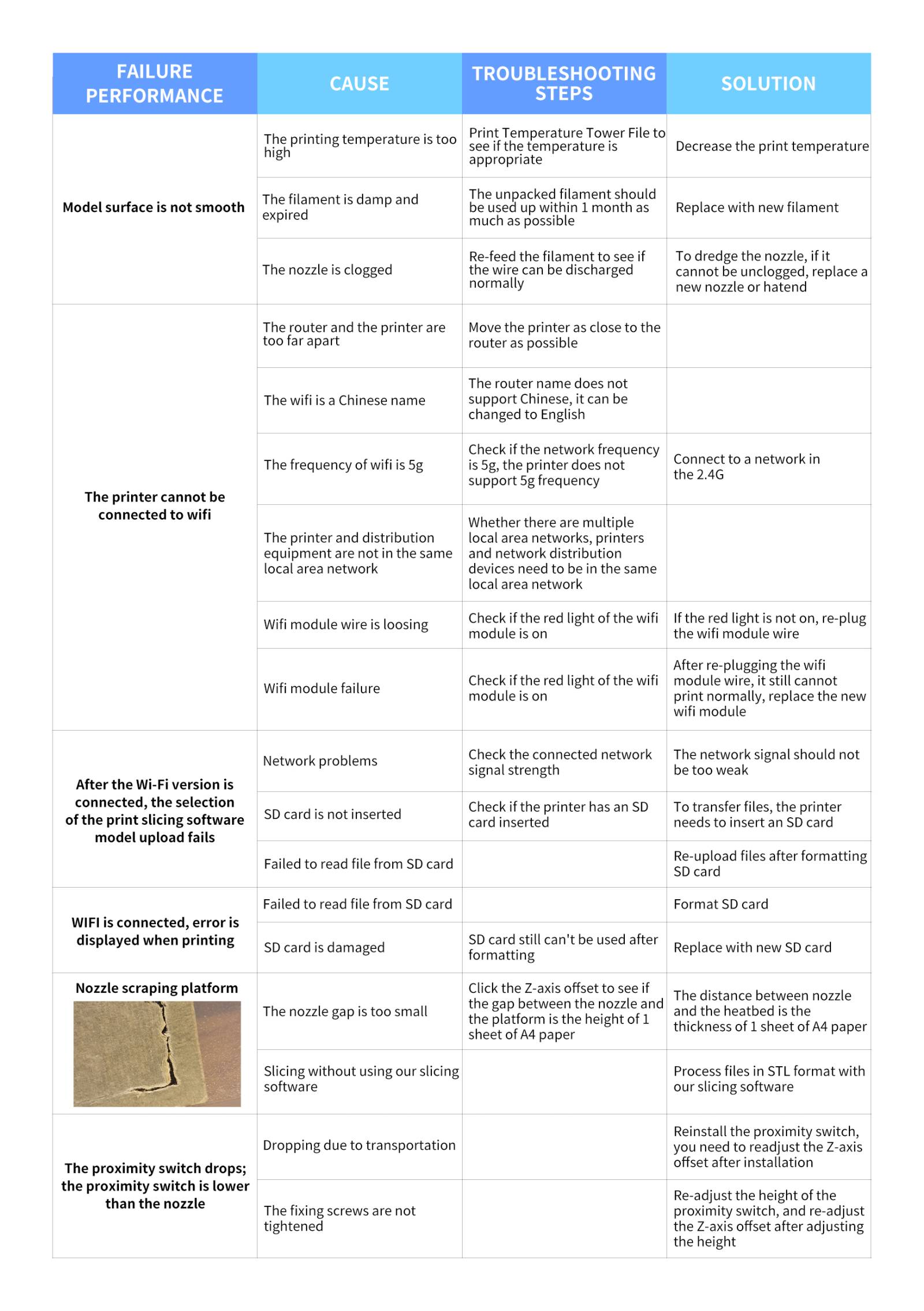

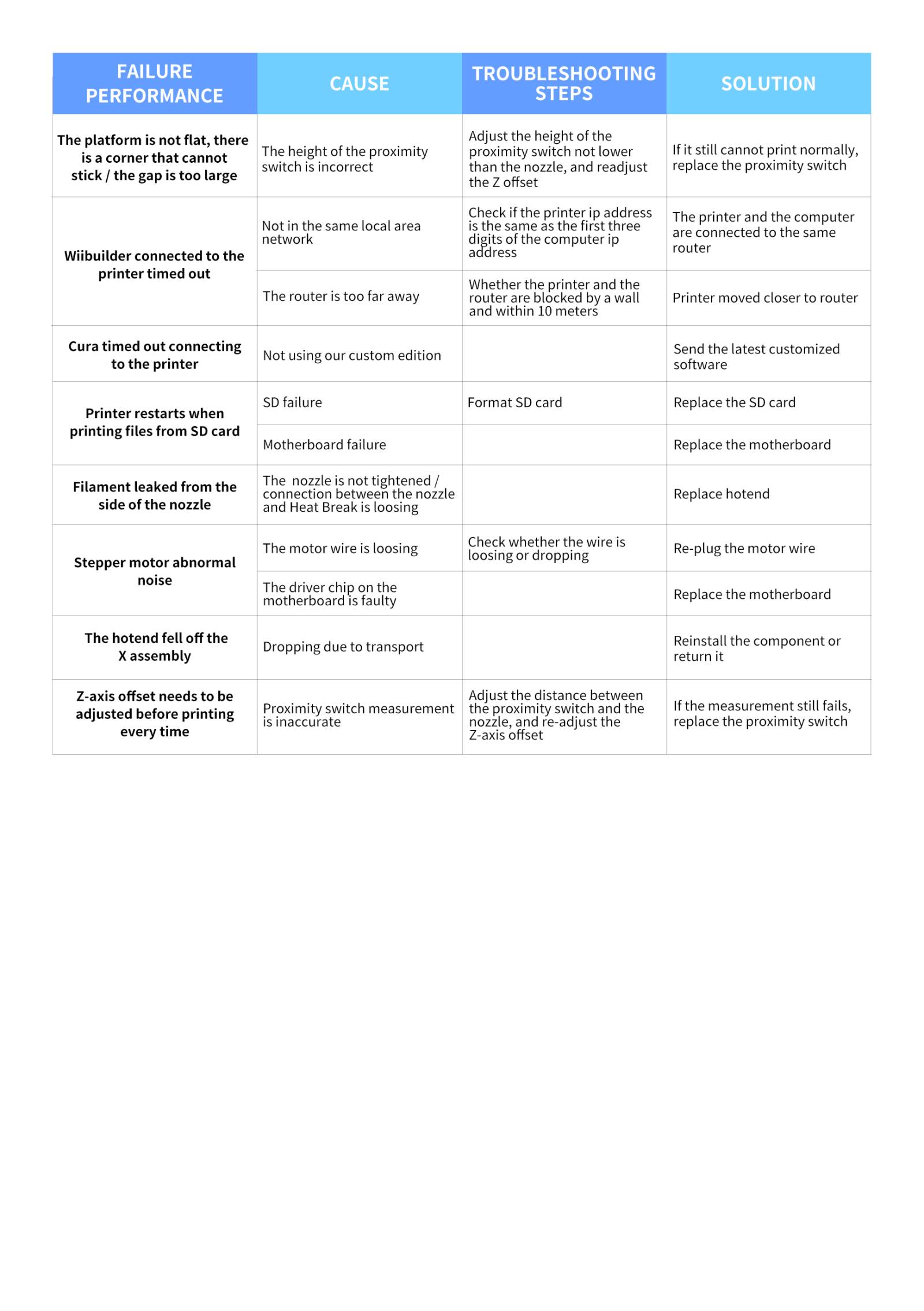

3D printing is still a technology that relies heavily on trial and error. It's nearly impossible to master the technology without getting your hands dirty. As there are no globally recognized standards in the 3D printer, material, or software manufacturing, it is vulnerable to a variety of printing problems. A multitude of 3D printer issues results in failed prints, which leads to a loss of business, if not your interest in the technology.

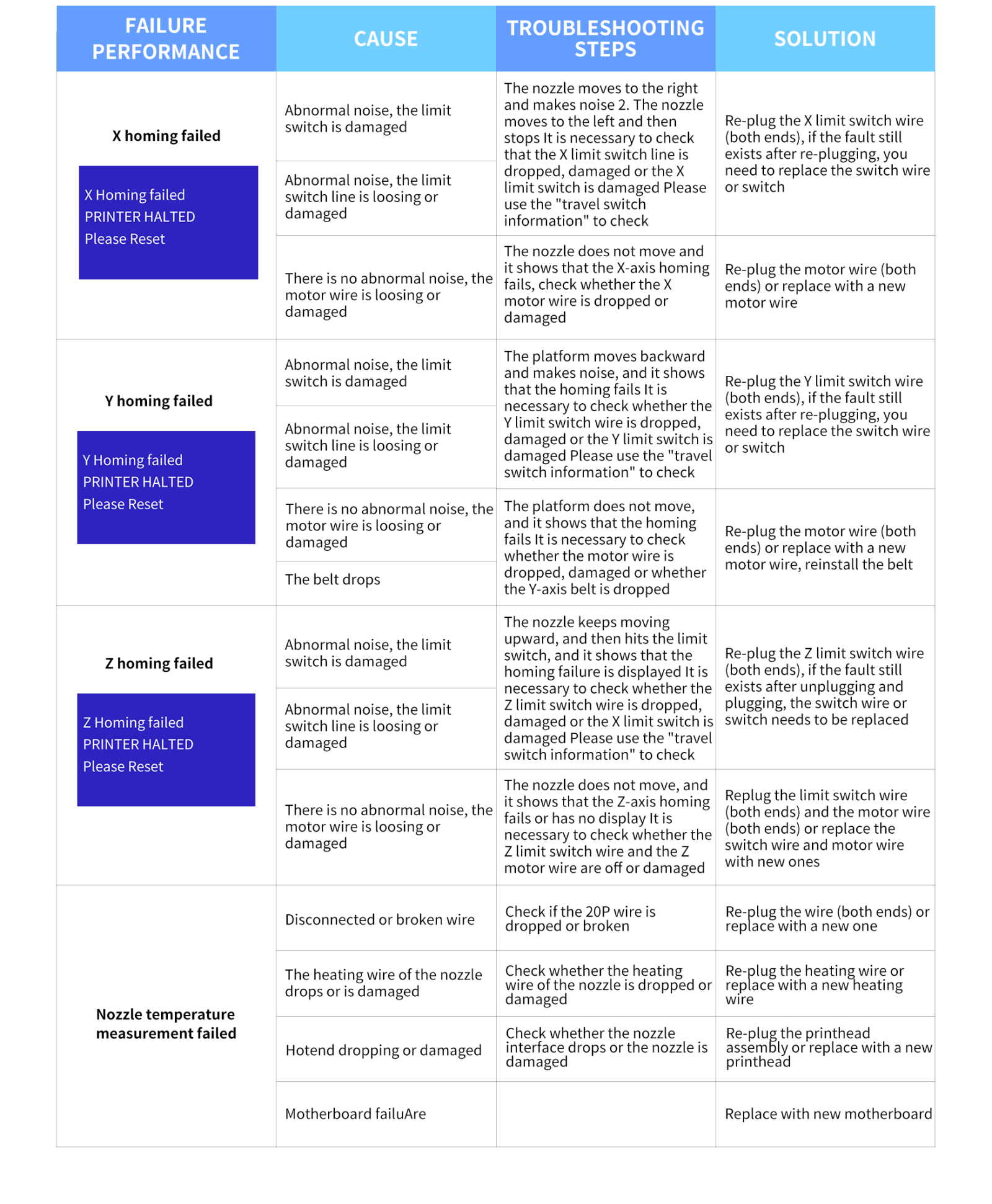

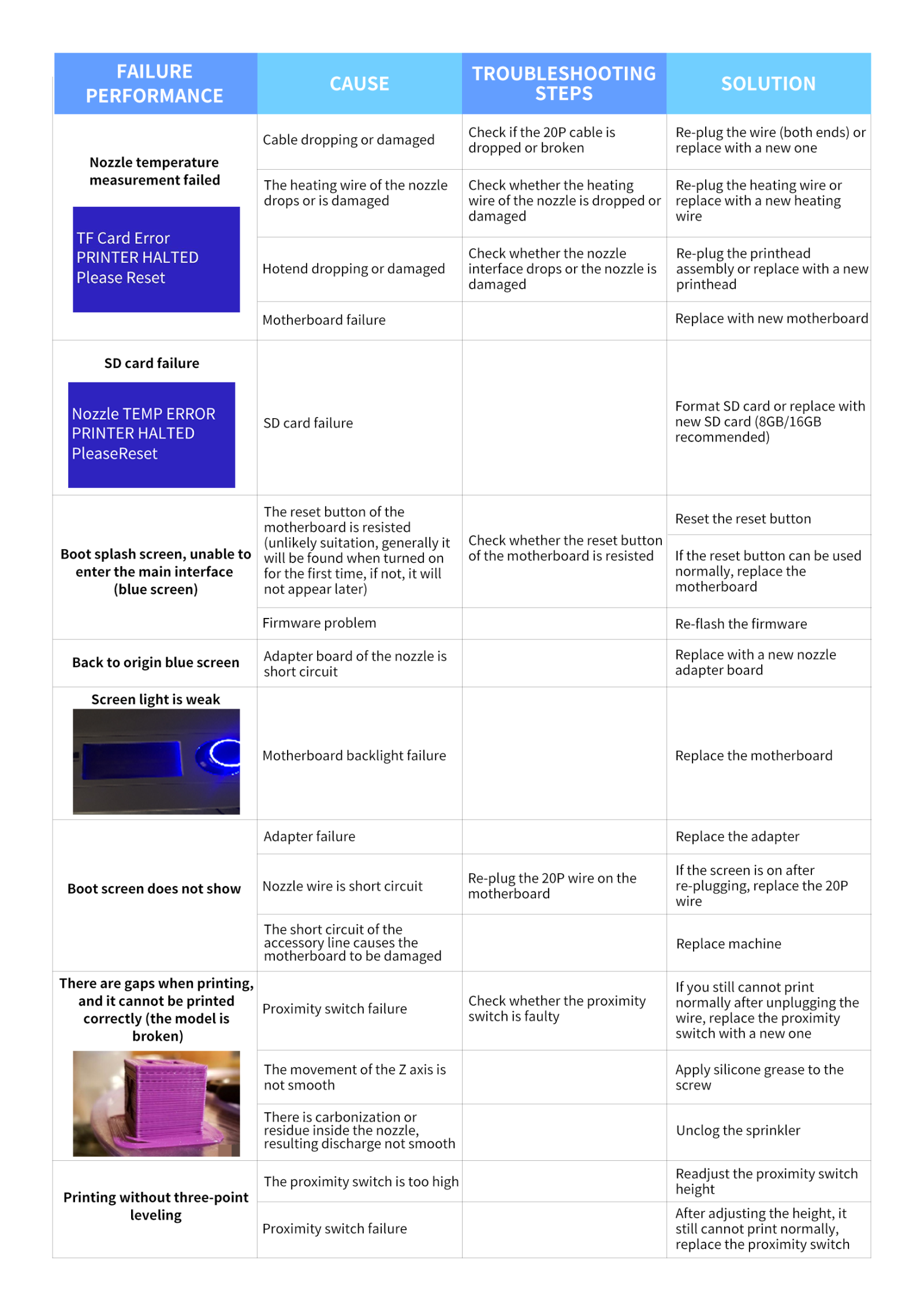

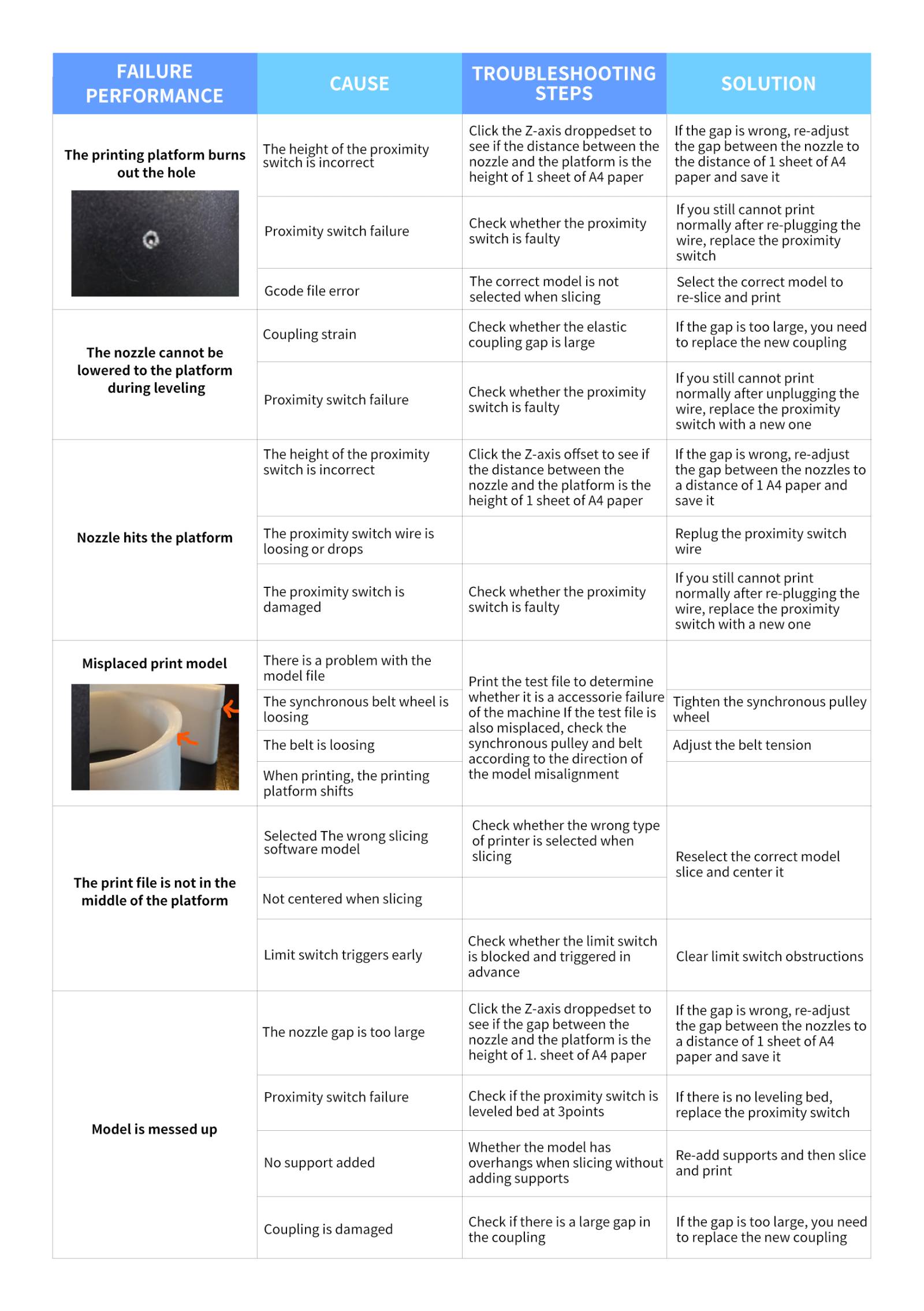

Tina2S has a fault reporting function, so fault diagnosis can be carried out from the following three aspects:

1. Nozzle clogging / the filament no coming out / nozzle not extruding material

| Fault | Reason | Solution |

| Nozzle clogging / the filament no coming out / nozzle not extruding material | ①The blockage of the nozzle caused by the damp filament is a common problem. | You only need to clean the nozzle to continue to use it. In severe cases, you need to replace the nozzle or hotend. —- video: https://youtu.be/B2v1ZOt-dn0 |

| ②The fan does not turn. | It needs to be replaced. —-video:https://youtu.be/6WSRCYo8FU4 |

2. No error reported,the model failed to print

| Fault | Reason | Solution |

| Print out of shape / filament like spaghetti / first layer adhesion | ①The platform is not sticky, and the Z-axis offset is wrong. | Please apply glue on the platform, and adjust Z-offset. —-video:https://youtu.be/zDwuzWy4hmE |

| ②The model parameters are incorrect | Slicing support, speed, layer height and other parameters will affect the printing effect, please refer to the manual, or send the model to customer service to help solve the problem. | |

| Stringing | The model parameters are incorrect | Slicing support, speed, layer height and other parameters will affect the printing effect, please refer to the manual, or send the model to customer service to help solve the problem. |

| Wifi cannot be connected | Tina2s does not display the IP, the device is not configured with a network. | Please configure the network according to the manual. |

| Wifi cannot be connected | Tina2s shows the IP, and the operation of networking is incorrect | Please turn off the firewall of Wiibuilder, and make sure it is the same network. Make sure the TF card is inserted. |

| USB cannot be connected | Incorrect operation | Please download the USB driver and select 10000 as the baud rate. |

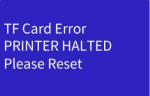

3. There is an error, and there is an obvious machine failure.

| Fault | Reason | Solution |

| Nozzle temperature measurement failed. | Hotend or cable is broken | Please replace with a new hotend. —-video:https://youtu.be/qe6wXHmxaeA |

| Fault | Reason | Solution |

| Nozzle heating failure | Hotend or cable is broken | Please replace with a new hotend.—-video:https://youtu.be/qe6wXHmxaeA |

| Fault | Reason | Solution |

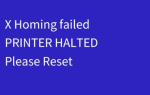

| Homing failure | Endstop or wire is broken | Please replace the endstop or endstop wire. —-video:https://youtu.be/hlgOGfGCEGU |

| Fault | Reason | Solution |

| Nozzle hit platform | The proximity sensor is broken | Please replace the proximity sensor. |

| Fault | Reason | Solution |

| TF card | TF card is broken | Please format TF card. |