Table of Contents

Filament

Type of filament

Supported: PLA,TPU, Print Temp<230°C, Bed Temp<50°C

Not supported: ABS, ASA, PETG, PC, NYLON, etc. Print Temp> 230°C, Bed Temp> 50°C (ABS bed temperature requirement exceeds TINA2S, so printing cannot be done)

Printing temperature

The printing temperature will be different for different types, brands, manufacturers, colors, and temperatures.

- PLA: Print Temp:180~220°C, Bed Temp:0~50°C

- Silk PLA: Print Temp:210~230°C, Bed Temp:30~50°C

- Gradient PLA: Print Temp:200~230°C, Bed Temp:40~50°C

- Wood PLA: Print Temp:200~220°C, Bed Temp:40~50°C

- PLA+: Print Temp:190~230°C, Bed Temp:30~50°C

- PLA Pro: Print Temp:210~230°C, Bed Temp:30~60°C

- TPU: Print Temp:190~235°C, Bed Temp:0~60°C

If the temperature is low, it will cause the nozzle to become clogged and non-stick.

If the temperature is high, it will cause stringing or bumps on the surface of the model that are not smooth.

If the printing effect is not satisfactory, please adjust the temperature to achieve the best.

Environmental Requirements

This 3D printer is for indoor use only, with an ideal ambient temperature of 15°C to 25°C.

- Below 10°C or in winter: Low temperatures can cause filament to become brittle and prevent proper extrusion, making it difficult for models to adhere to the platform. Increase the nozzle temperature by 15°C, set the platform temperature to 60°C, and apply adhesive.

- Below 0°C: The device will not start.

- Above 30°C or in summer: Print quality will significantly decline. High temperatures may cause stringing issues and the nozzle may clog. Please lower the nozzle temperature appropriately.

Filament causes clogging

In addition to fan, incorrect insertion of the filament tube and operational reasons, the filament is also one of the main causes of clogging. Please troubleshoot according to the following points:

①Tina2 only supports PLA/TPU

The print temperature is <230℃, (Tina2s bed temperature is <50℃). Please confirm the filament type.

②Low Print Temperature

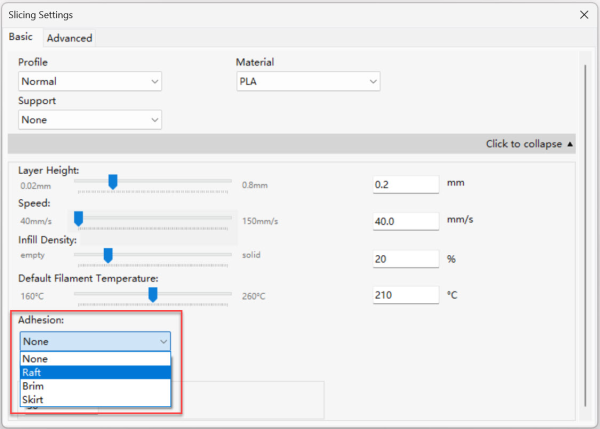

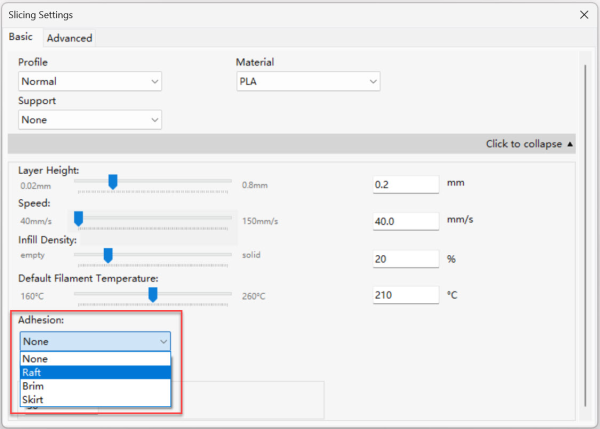

Please increase the nozzle temperature by 10℃, set the bed temperature to 50℃ and apply glue.(Tina2 Basic cannot set the bed platform temperature, please adjust the Z-offset, Slice settings add “Raft”, and increase the indoor temperature).

③ If it is winter

It will cause the filament to fail to come out and become brittle. Please increase the nozzle temperature by 15℃, set the bed temperature to 50℃and apply glue.( Tina2 Basic cannot set the bed platform temperature, please adjust the Z-offset, Slice settings add “Raft”, and increase the indoor temperature).

④The filament is wrapped around

Please arrange the filament well.

⑤ If the filament is damp or dusty

It will cause the nozzle to become clogged, so please do not use it.

⑥The nozzle accumulates a lot of dust and dirt particles over time

It may also accumulate material residue, causing the nozzle passage to become clogged with debris. To avoid this problem, you should unclog the nozzle regularly.

Other brands of filaments cause clogging or poor model

If the printing results are poor or clogging occurs after changing to new filament, please check the brand of filament being used. We recommend using filaments recommended by our brand.

Filaments recommended by our brand have been tested to ensure high printing quality under default settings. Third-party filaments may have different formulations, requiring manual adjustment of printing settings. Therefore, we recommend beginners use filaments from our brand.

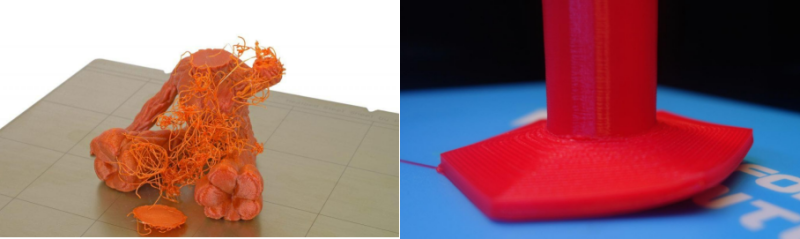

The filament causes the model to become non-stick/Warping

In addition to Z-axis offset, nozzle height, proximity switch failure, fan, printing speed, G-Code errors, etc., filament can also cause the model to become non-stick:

①Tina2 only supports PLA/TPU

The print temperature is <230℃, (Tina2s bed temperature is <50℃).

②Low Bed Temperature

Please increase the nozzle temperature by 10℃, set the platform temperature to 50℃, apply glue on the platform, and add padding to the model slice setting.(Tina2 Basic cannot set the bed platform temperature, please adjust the Z-offset, increases the first layer by 15~20°C,and increase the indoor temperature).

③If it is winter

Low temperature will cause the filament to fail to come out and become brittle, etc. Please increase the nozzle temperature by 15℃, set the platform temperature to 50℃, apply glue on the platform, and add padding to the model slicing setting.(Tina2 Basic cannot set the bed platform temperature, please adjust the Z-offset, increases the first layer by 15~20°C,and increase the indoor temperature).

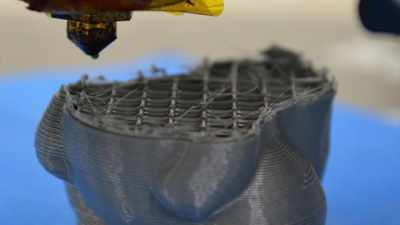

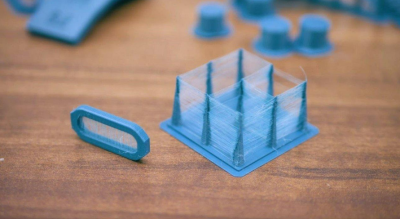

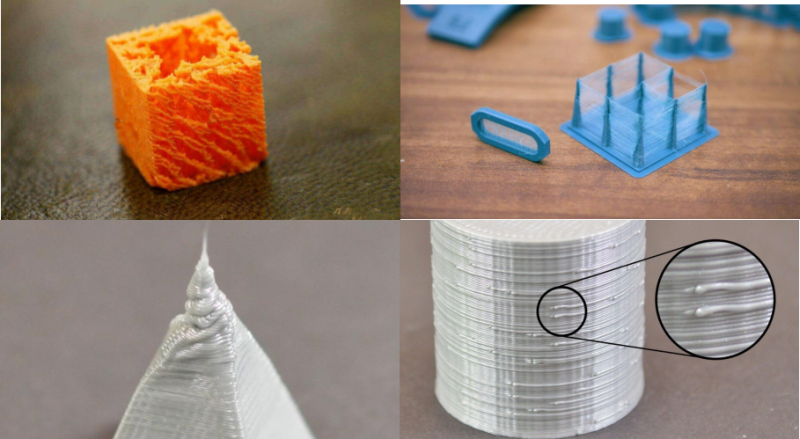

Stringing

This is yet another common 3D printer issue that many beginners face. Stringing is a problem that occurs when thin strings of material, similar to whiskers, remain on the surface of a 3D printed part, affecting the print's surface finish. It increases post-processing effort and is an unfavorable element.

① If the print temperature is high

It will lead to wire drawing, bubbles or bumps on the surface of the model that are not smooth.

②If it is summer

Drawing problems will occur. Please lower the nozzle temperature appropriately.

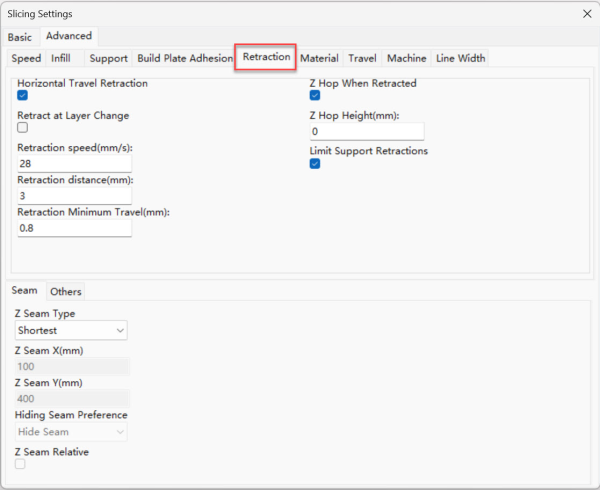

③Slicing settings

Some special models require slicing settings, such as Retraction.

Retraction is a critical parameter that influences stringing. Retraction, by definition, is the reverse movement of the filament to prevent excessive oozing of the melted filament. To find the best parameters, you'll have to do a lot of trial and error.

The surface quality of the model is not good

①The print temperature is high

It will lead to wire drawing or bumps on the surface of the model that are not smooth.The flow of the material is affected by the print temperature. Lower the temperature and the flow of material will be reduced, resulting in under-extrusion. The effect of this can be seen in the print, where gaps in printed layers can be seen. Furthermore, a higher temperature will result in over-extrusion, so you must take care to set a balanced print temperature to avoid both issues.

② If the filament absorbs moisture

Moisture bubbles will form inside the filament and cannot be used. To avoid this problem, store materials in a cool, dry place.

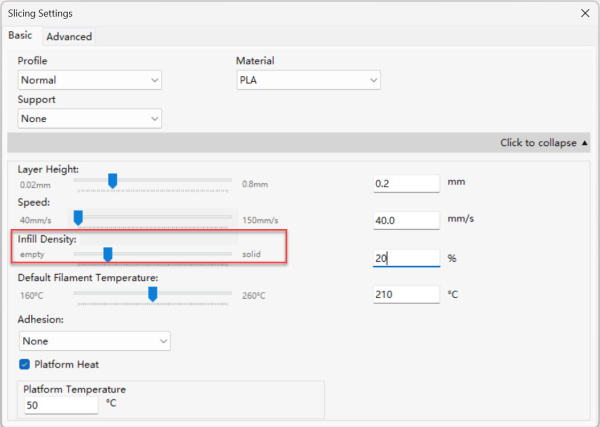

③Slice settings

Some special models require slice settings, such as Infill.

The use of sparse infill can cause a gap in the top layers. A low-density infill indicates that there is a large gap inside the model, and the deposited material falls into the infill gaps instead of forming the top layers. As a result, the top layer has gaps or holes. Even in this case, you can try the first solution to compensate for the poor infill. For such an issue, you need to increase the infill percentage.

④Filament diameter is 1.75mm

If you use the incorrect filament for printing, one of two issues will occur. If you slice a model considering a smaller filament diameter instead of the larger filament that is actually in use, it will result in over-extrusion and vice versa. As a result, it is critical to use the appropriate diameter filament and slice the model appropriately.

This problem is most frequently encountered by those of you who use smaller filament diameters (1.75mm). If none of the above solutions work for you, you can try using a 2.85mm (also referred to as 3mm) diameter filament.

Over-extrusion occurs when your printer extrudes more material than is ideal, while under-extrusion occurs when it extrudes less material than is ideal. Both these conditions are detrimental to the 3D print and can lead to failure, in addition to wasting material, time, and effort.

The intriguing aspect is that both of these problems have similar solutions. Both problems can be avoided if the parameters are set correctly.